The robotics industry is not new, but with recent technology advancements, it is becoming more sophisticated, accessible, and intertwined with daily life. What was once the domain of industrial assembly lines has now spilled into warehouses, restaurants, and city streets; from surgical robots and autonomous delivery vehicles to warehouse drones and AI-driven customer service assistants. The field is no longer just about machines performing repetitive tasks; it is about intelligent systems learning, adapting, and collaborating with humans to solve complex problems.

The Global Robotics Landscape

The global robotics industry has grown into one of the defining sectors of modern technology, shaping manufacturing, healthcare, logistics, and even everyday services such as pest control. Annual installations of industrial robots surpassed half a million units in 2024, more than double the levels seen just a decade ago. Asia dominates this landscape, accounting for nearly three-quarters of global demand, with China leading in volume and South Korea and Japan excelling in density and advanced applications. Europe, particularly Germany, continues to stand out in precision engineering and robotics integration.

Alongside industrial machines, service robotics has emerged as a fast-growing category, with applications in logistics, healthcare, construction, and inspection opening new frontiers for innovation and commercialisation.

Singapore’s Strategic Position in the Robotics Industry

Amid this competitive global scene, Singapore occupies a distinctive position. Although the city-state lacks the scale and cost advantages of larger manufacturing economies, it has carved out a role as a hub for high-value robotics innovation and commercialisation.

Singapore consistently ranks among the top countries in robot density relative to its workforce, particularly in electronics, precision manufacturing, and logistics. National strategies such as the National Robotics Programme and the broader RIE2025 research and innovation plan have placed robotics and embodied artificial intelligence at the heart of Singapore’s future economy. Through these initiatives, the government funds cutting-edge research, supports translational projects that move technologies from labs to industry, and provides testbeds in areas such as ports, airports, and hospitals where robotics solutions can be trialed in real-world conditions.

Singapore’s Strengths and Challenges

Systematic Ecosystem

Singapore’s strengths lie in its ecosystem rather than sheer production capacity. The presence of multinational corporations (MNCs), a robust intellectual property framework, and a willingness among corporations to pilot new technologies make the country a natural launchpad for robotics startups and international firms looking to expand in Asia.

Scaling Platform

Initiatives like RoboNexus bring together researchers, startups, and industry players to speed up the path from prototype to market. At the same time, Singapore’s logistics infrastructure, healthcare system, and urban environment provide rich opportunities for deployment in high-value niches. Where China dominates mass production, Singapore focuses on precision components, systems integration, and software-driven robotics solutions that can be scaled regionally and globally.

High Operating Costs and Limited Space

Yet the industry also faces challenges. Singapore’s high operating costs and limited land base mean it cannot compete as a mass manufacturing hub for robotics hardware. Instead, it must continue to position itself as a centre for intellectual property creation, systems innovation, and robotics-as-a-service business models.

Building a Skilled Workforce

Another persistent challenge is talent. While Singapore has developed strong capabilities in engineering and computer science, scaling the robotics industry requires a deep pool of mid- and senior-level specialists who can bridge research, design, and commercialisation. However, skilled talent is still a challenge within the local workforce.

The Role of Inbound Immigration in Singapore’s Robotics Industry

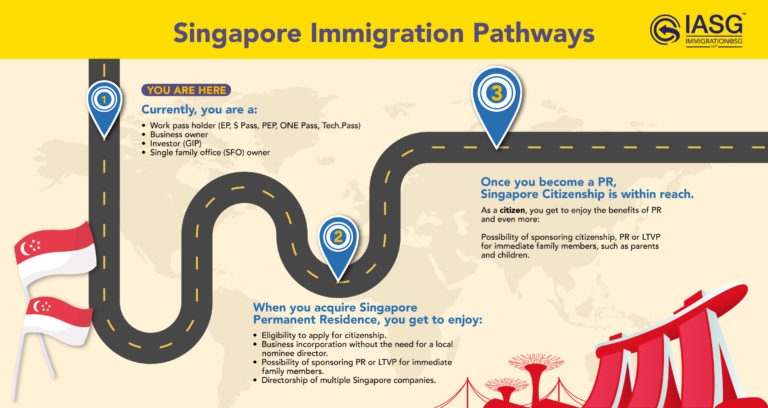

Immigration has been a quiet but essential enabler of Singapore’s robotics ambitions. Robotics companies often require highly specialised expertise ranging from mechanical design of compliant manipulators to perception engineering and control systems. These talents may not yet exist in sufficient numbers locally. Employment Passes (EP) and targeted immigration routes allow firms to bring in these rare skill sets quickly.

In recent years, Singapore has refined its immigration policies to prioritise high-skilled professionals, raising salary thresholds while introducing schemes such as Tech.Pass that are tailored to experienced founders, entrepreneurs, and industry leaders. These measures ensure that the country attracts top-tier talent who can fill critical technical gaps, anchor multinational R&D centres, and mentor the next generation of local engineers.

Beyond technical expertise, inbound immigration provides other advantages. Senior hires often bring entrepreneurial experience and venture networks that accelerate the growth of startups, connecting Singaporean firms with overseas markets and funding opportunities. MNCs also find Singapore attractive as a regional headquarters because they can relocate global teams here, reinforcing the city-state’s role as an innovation hub. Most importantly, foreign professionals contribute to knowledge transfer. Local engineers and technicians learn advanced robotics integration skills directly through collaboration, multiplying the long-term value of each hire.

Can Robotics Replace Immigration in the Future?

In recent years, robots have begun cooking up a storm in commercial kitchens. From automated wok stations that stir-fry with precision to robotic baristas that brew hundreds of cups an hour, the food and beverage (F&B) industry has become one of the most visible testbeds for robotics in Singapore. These innovations are not just futuristic novelties; they are born out of necessity.

Singapore’s F&B sector, known for its relentless pace and razor-thin margins, has long struggled with manpower shortages. Recruiting and retaining workers has become increasingly difficult. Local employees often shy away from long, physically demanding shifts, while employers face rising wage expectations and tighter rules on hiring foreign workers. Immigration policies have evolved to prioritise higher-skilled professionals, leaving labour-intensive industries scrambling for solutions.

This labour squeeze has pushed many businesses to look toward automation as a survival strategy. Robots don’t need rest, salaries, or work permits and they can operate around the clock. Smart kitchens equipped with robotic systems can prepare consistent meals faster and more safely, reducing dependence on transient labour. In theory, this could ease Singapore’s reliance on foreign workers in low-wage sectors, a dependency that has long shaped its economic and immigration policies.

However, the rise of robotics also presents a paradox. While automation may reduce the need for certain types of manpower, it simultaneously increases the demand for another: skilled engineers, technicians, and systems integrators who design, maintain, and improve these machines. The same tightening of immigration that affects F&B service staff also impacts the ability to bring in such technical specialists essential to keeping the robotic infrastructure running.

Thus, rather than fully replacing immigration, robotics reshapes it. The future workforce may consist of fewer manual workers but more high-skilled foreign professionals who can build and sustain automation systems. The balance between technology and talent will determine whether Singapore’s industries can continue to grow without losing their competitive edge.

In essence, the robots may take over the frying pans and serving trays, but behind every machine stands a network of global human expertise. The challenge for Singapore will be ensuring that its immigration, education, and innovation policies evolve together, so the country remains both technologically advanced and economically inclusive.

Balancing Policy and Growth

Singapore’s immigration strategy, therefore, complements its research and innovation policies. By investing in testbeds and R&D while simultaneously ensuring a pipeline of global expertise, the country positions itself as a place where high-value robotics ideas can be developed, tested, and scaled. The policy trade-off is clear: while raising salary thresholds for foreign professionals increases hiring costs, the productivity and ecosystem benefits outweigh the risks, especially in a sector as complex and fast-moving as robotics.

Future of Robotics Industry in Singapore

In the broader global context, Singapore does not aim to rival China in sheer production numbers. Instead, it plays to its strengths as a commercialisation node, a place where public R&D, private investment, corporate partnerships, and international talent converge. By focusing on precision, reliability, and trust, Singapore can sustain its role as one of the most influential robotics hubs in Asia Pacific.

The future of robotics in Singapore will hinge on its ability to maintain this balance. Continued investment in R&D, strong support for startups, and a forward-looking immigration framework will allow the country not only to participate in the global robotics revolution but to shape it in ways that reflect its strengths: innovation, trustworthiness, and connectivity. In an industry increasingly defined by both scale and sophistication, Singapore’s edge will be in demonstrating how a small nation can lead through strategic focus and global openness.